Functional safety

Functional Safety Background

Development towards machine autonomy sets growing requirements for functional safety. Also legislation such as the EU Machinery Directive 2006/42/EC sets requirements which machine manufacturers must comply to with their products. New revisions of C-type standards have been published to align application-specific requirements with the Machinery Directive and state-of-the-art technology.

For these demands, Epec has developed products like SL84 Safety Control Unit and a software ecosystem to meet all the technical requirements as well as business objectives. Our objective is to provide machine manufacturers with a complete solution.

Application Development Approarch

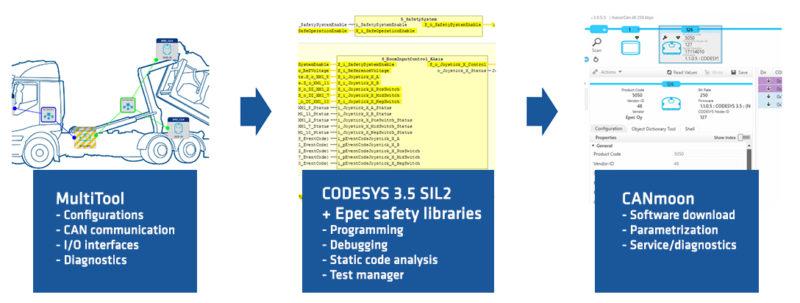

Epec’s application development tool chain streamlines the making of safety application:

- Make all the needed configurations with Epec MultiTool (all safety-related items are highlighted with yellow), MultiTool then generates a code template

- Continue the programming with CODESYS using Epec’s pre-certified safety libraries and normal CODESYS libraries

- Once the application is completed, use Epec CANmoon to download the software in safety unit

To enhance developing safety-related software we have prepared an efficient toolchain to make the safety development process fluent:

- Epec provides all the needed HW and SW for functional safety.

- Software consists of pre-certified safety libraries and the tool chain for creating an application

INTERESTED?

information

FINNISH KNOWLEDGE

tested, designed and produced in finland.

Epec control systems are made 100% in Finland. We are a control system expert, specializing in intelligent control systems and information systems for even the most demanding conditions. Epec’s organization and processes have been fine tuned to cooperate with large international customers.