Epec invests in a responsible new electronics factory in Seinäjoki, aiming for carbon neutrality

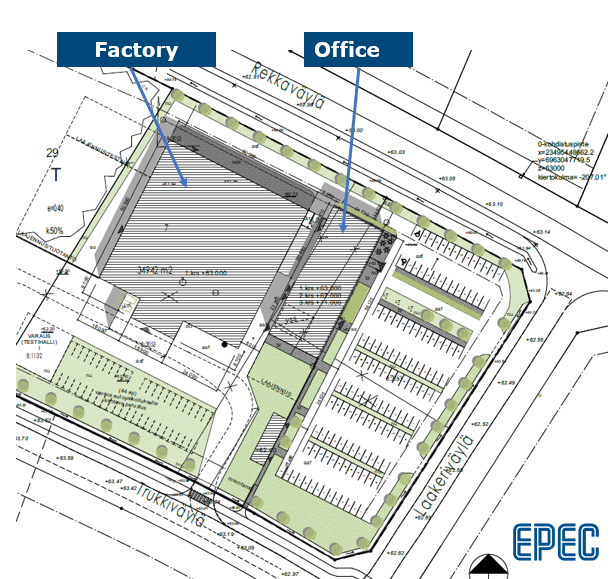

Epec opens a new smart and sustainable factory in Seinäjoki, Finland. ESF1’s (Epec Smart Factory 1) total of 8,500 m2 includes factory space and a three-story office. Epec’s headquarters with its R&D, engineering and production functions has moved to new premises from its previous premises on the Seinäjoki campus. In addition to Seinäjoki, the company also has offices in Tampere, Turku and Kuopio in Finland, and in China, USA and Holland. The construction of ESF1 started in spring 2022 and the new factory started operations in Q4/2023

“The investment is significant for Epec, enabling the strong growth we are currently experiencing. Digitalisation and electrification are rapidly increasing their share of the non-road machinery and commercial vehicle sector, which has opened up new and expanding markets for Epec. With a state-of-the-art factory, we are able to meet growing demand and increasingly stringent customer requirements, for example in terms of manufacturing processes.”

– Jyri Kylä-Kaila, Managing Director of Epec

ESF1 FACTS

- 8500m2

- Construction started in April 2022, the factory started operations in Q4/2023.

- Plot is 35 000 m2 including reservations for 5500m2 factory/office expansion and test hall.

- The factory meets the most demanding customer requirements and standards.

SUSTAINABILITY

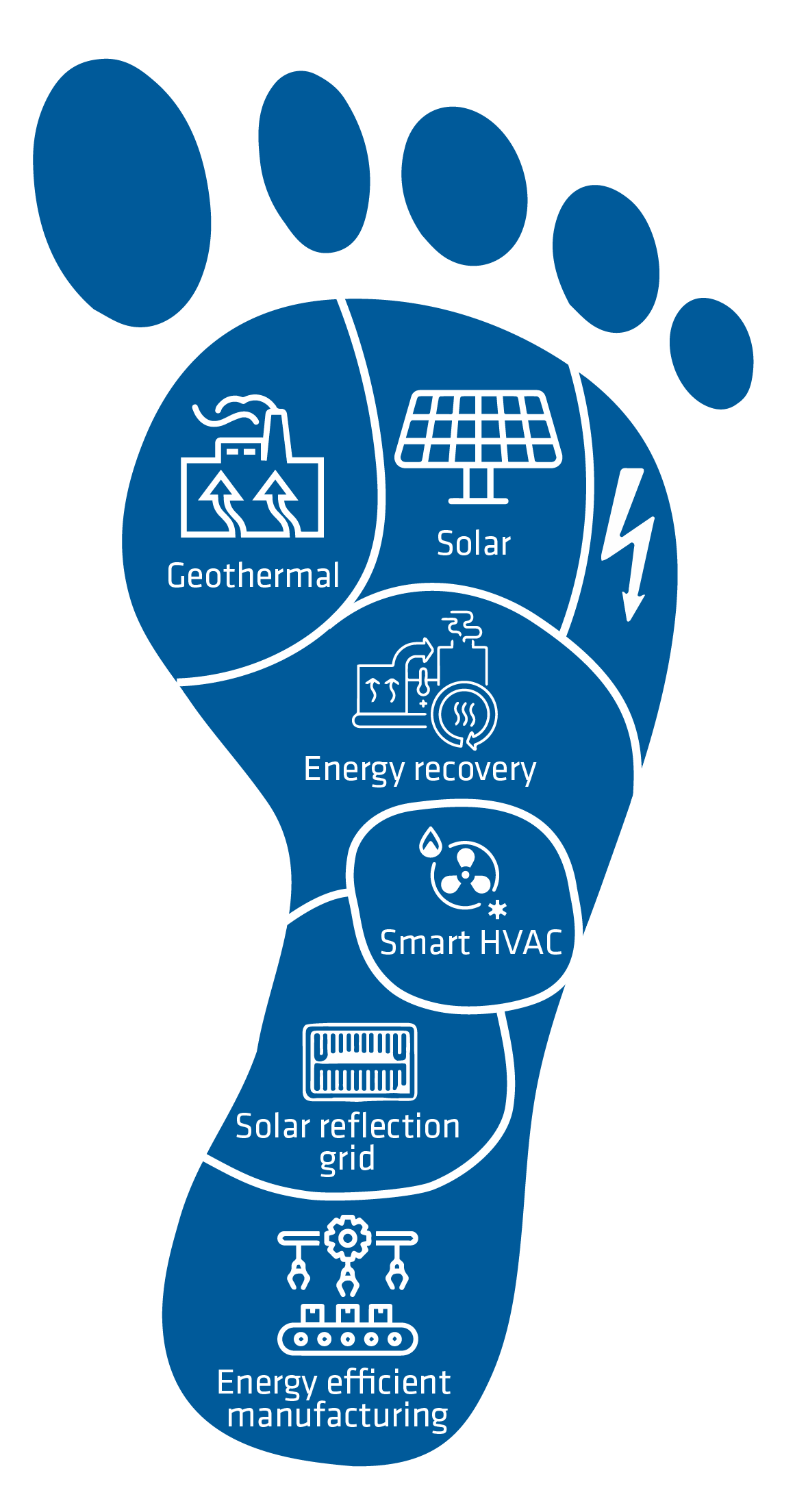

- Epec is fully committed to promoting sustainable development, energy efficiency and reducing its carbon footprint.

- ESF1 aims for carbon neutrality during its use and will employ sustainable manufacturing processes.

- over 600 solar panels (210 MWh/year

- The common areas are heated by a geothermal system.

- The heat generated by the factory is recovered by efficient needle heat exchangers.

- The need for cooling energy is significantly reduced by an aluminium grille on the office wall.

- All electricity and heating energy is sourced from renewable resources.

EMPLOYEES

- Improved working conditions, work safety and production flow & efficiency.

- Growing demand for new professionals

- For more information on open positions, see ura.epec.fi

“The productivity of the factory has been maximized by simulating and optimizing the production and material flows, exploiting the opportunities offered by digitalisation and waste energy.”

“In practice, digitalisation in this case means a high level of automation, data utilisation, robotics and intelligent building automation. Particular attention has also been paid to safety and comfort at work. Overall, the testing and production technology is state-of-the-art. The new and modern production facilities provide Epec with excellent opportunities to further develop and grow our operations, expand our product portfolio and increase our manufacturing capacity. There is also plenty of room for expansion on the site to accommodate for future growth.”

– Eeva Koskela, Supply Chain Director

Increased staffing needs

“Epec has grown rapidly in recent years and the recruitment needs are still high. The greatest need at the moment is for various product development and programming positions, but other specialists, assemblers and administrative staff are also needed.”

– Riikka Rajala, HR Manager

Construction of the factory started in June 2022 and was completed in September 2023

NEXT GENERATION

SUSTAINABLE MANUFACTURING

Extreme conditions?

– Bring it on!

The toughest products are formed for the toughest environments. Epec control units are robust and reliable, they are designed and manufactured to withstand harsh conditions: high mechanical shocks and vibration, heat, cold and different chemicals.

Order Epec newsletter