Epec SL8X Control Unit

EPEC SL8X CONTROL UNIT

Epec SL8X Control platform delivers high-performance real-time control, functional safety, and exceptional flexibility, making it ideal for demanding applications in off-highway machines and non-road vehicles.

This platform is highly adaptable to different system topologies, including both centralized and distributed architectures. Centralized systems offer the benefit of simplified wiring, reduced hardware complexity, and streamlined maintenance, while distributed systems provide greater scalability and adaptability for complex setups.

Key Benefits:

- Versatile Programming: Adaptable to both centralized and distributed systems, offering seamless integration with multiple programming environments.

- Advanced Communication: Enables fast and reliable data exchange with support for various communication protocols, ensuring real-time responsiveness.

- Durable Design: Built to endure harsh environments, with extensive input/output options to support complex configurations.

- Simplified Configuration: Compatible with Epec’s MultiTool software for easy configuration, diagnostics, and simulation, reducing setup time.

- Functional Safety: Designed to meet the highest safety standards, supporting secure and reliable operation.

The SL8X platform is a modular product family offering versatile solutions for functional safety and control. Platform includes CODESYS and C programmable safety controllers, CANopen safety responders, and Ethernet safety responders, all designed for flexible integration into various safety-critical systems. This platform also provides a wide range of customization possibilities for diverse machine applications.

Accelerated Time to Market:

Epec offers a set of pre-certified safety libraries and software tools to optimize machine development, helping customers bring their products to market faster and more efficiently.

SL8X is engineered to deliver performance, reliability, and flexibility, making it the perfect solution for advanced control systems in industrial applications.

Virtual Development Tools:

To accelerate development and enable design without the need for physical hardware, the SL8X platform offers a virtual version of the CODESYS programmable SL8X unit in Epec MultiTool Simulator. MultiTool Simulator streamlines the development process, reduces prototyping costs, and enables faster and automated testing iterations.

Cybersecurity:

- Epec is certified with ISO/IEC 27001, ensuring compliance with international information security standards.

- Customers can utilize Epec’s control system and software development services, which consider cybersecurity as a key aspect.

- Up to SIL2 (IEC 61508:2010 and EN IEC 62061: 2021) and PLd/Cat. 3 (EN ISO 13849-1:2015)

- Processor: Versatile 32-bit functional safety controller

- Flash memory: 8 Mbyte

- RAM: 1,5 Mbyte

- Non-volatile memory: 32 kbyte

- Customer application size: 1,8 Mbyte

- CAN: up to 6

- Ethernet: up to 4 (1 x 100Base-TX and 3 x 100Base-T1)

- I/O: up to 100 (49 inputs + 51 outputs)

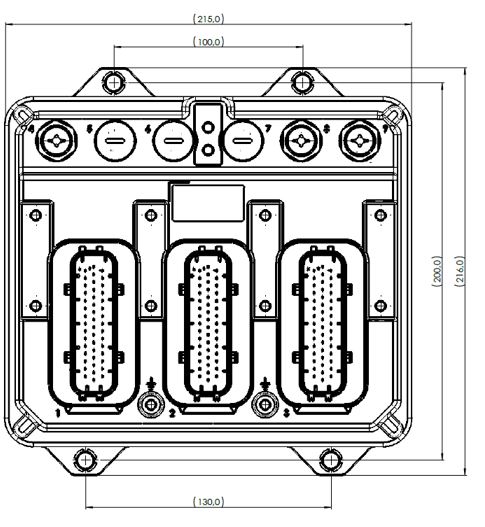

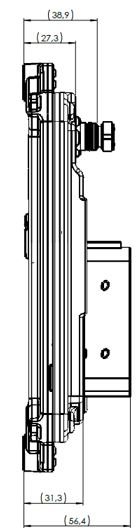

- IP class: IP69k

- Temperature range: -40 … + 85 °C

-40 … +185 °F - Connectors: up to 3 x LEAVYSEAL 46 pin, up to 6 x M12

- Programming: CODESYS 3.5 (SP19), C programming, CANopen Responder, Ethernet Responder, Epec MultiTool, Matlab/Simulink support

- CODESYS V3 Safety SIL 2 programming

- Supported protocols: CANopen, CANopen Safety (EN50325-5:2010), SAEJ1939 (Functional Safety Communications Protocol SAE J1939-76:2020), ISOBUS, CAN over Ethernet

- Extensive set of pre-certified PLCopen libraries for safety related applications

- 2 x RGB diagnostic LED for quick status check and fault detection

| Symbol / Name | Explanation |

| CE | This product complies with the requirements set in the CE Standard. |

| E17 | This product is certified with normal automotive (E17) EMC (electromagnetic compatibility) standards. |

| RoHS2 | This product complies with the RoHS directive (The Restriction of the use of certain Hazardous Substances in Electrical and Electronic Equipment). |

| EU declaration of conformity | This device is in compliance with Directive 2014/53/EU. EpecSL8XDeclarationOfConformity |

| Ordering code | E300SL8X1-01-DD11 |

| Technical Manual | MAN000814 |

| CAN | 6 |

| M12 Power | 2 |

| Ethernet | 4 |

| Status LED | 2 |

| 5 V REF | 3 |

| 10 V REF | 2 |

| I/O GND | 13 |

| PWM/DO | 46 |

| AI/DI | 30 |

| PI/DI | 18 |

| Wiring harness ID | 1 |

| KL15 | 1 |

FINNISH KNOWLEDGE

tested, designed and produced in finland.

Epec control systems are made 100% in Finland. We are a control system expert, specializing in intelligent control systems and information systems for even the most demanding conditions. Epec’s organization and processes have been fine tuned to cooperate with large international customers.