The medium length of drill rigs in oil and gas wells varies from 1000 meters to 1200 meters. Six and nine meter drill rigs are lifted from the bore holes in 6 and 9 meter batches. The new CAN-based control system of a 75-digit Flush by unit device for gas and oil well maintenance by an Australian company Exploration Drill

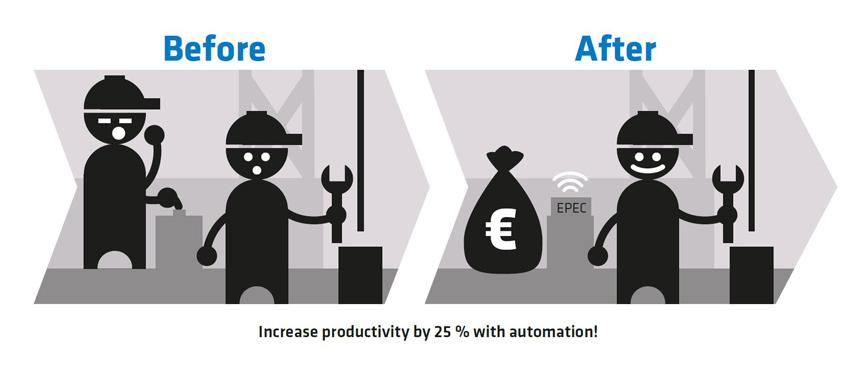

Rig (XDR) enables winching the rigs automatically. The automation of this work phase has boosted work productivity by 25 per cent.

25% productivity boost

to gas and oil mine maintenance with

an intelligent control system

Before, drill rigs were lifted and lowered into the wells manually. The work was very slow and prone to user errors. Now, the control system winches the rig on behalf of the user and communicates in real time in which height the rig is going up or down.

With the control system the user can also set a height limit to, for example, six meters and activate the lifter, which then stops at the set height automatically. “You don’t have to think it through and reset anymore if the rig is in 6 or 6,1 meters. The automation of the winching speeds up the work considerably”, describes the representative of the company.

Automatic stopping also prevents errors. You can’t run the wire cable through the attachments of the mast anymore when performing maintenance on the machine. Previously it was possible if the user was careless and didn’t stop the winching early enough.

Epec’s control system in XDR’s Flush by unit

- speeds up the winching of the rigs and reduces user errors, because the system stops the rigs at exactly the right time

- the end user gets more information and more accurate information about the functionality of the machine, which enables them to, for example, time the replacement of the wire cable better

- safety has been improved with, among other things, angle sensors

XDR Uses:

Epec 2038 Control Unit

EPC-i10 Mobile PC