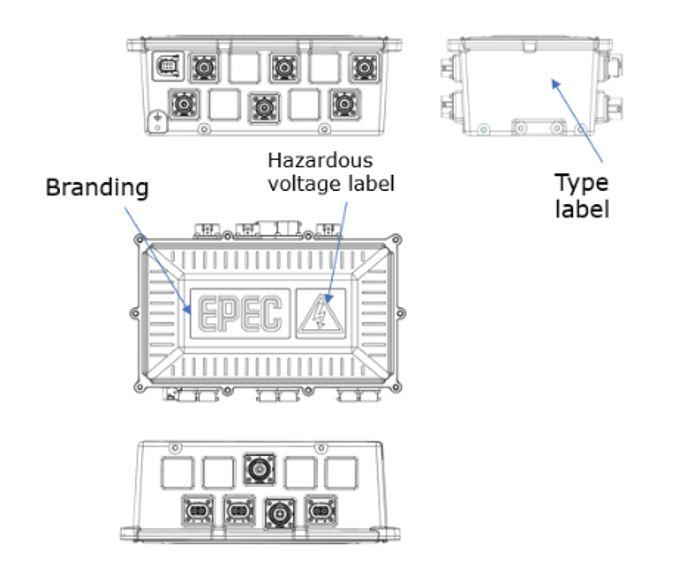

Passive PDU

EPEC PASSIVE PDU

TRACTION VOLTAGE POWER DISTRIBUTION UNIT FOR ELECTRIC VEHICLES / MACHINES TRACTION AND AUXLIARY HIGH VOLTAGE SYSTEMS:

- Passive unit enables safe connection of the machine high voltage component

- Fuse protection for high and low current component conduits

- Hazardous voltage interlock loop (HVIL) for connectors and cover

- PDU can be equipped optionally with system insulation measurement unit

- Water cooling for reaching high performance

- Robust unit which is configurable for different circuit demands

| Feature | Value | Note |

| Thermal management | Liquid cooling option | Water/glycol mix |

| Operating current | 350 A (RMS) | Continous current |

| Current peak | 500 A | 10 s |

| HW Connections | 4x High current IO (300 A RMS) 3x Low current IO (50 A RMS) | IO’s and connection types can be varied based on customer need |

| Safety | All connections IPXXB and with HVIL | - |

| HVIL circuit | Covers and connectors included | Safety lid included (min 10 s safety time from cover opening) redundant cover opening circuit. |

| Insulation monitoring | Full HV-system monitoring | Optional, Alarming limit: min 500 kΩ |

| Fuses | High current IO up to 400 A /900 Vdc Low current IO up to 70 A /900 Vdc | Fuse sizing shall be done at integration project with customer |

| Operating condition | In operation -40 °C to +60 °C IP67 and IP69K Max 2000 m | Designed for harsh environment |

| Output power (continuous) | 100- 270 kW | - |

| Size | 445 x 295,1 x 165 mm | prototype |

| Overall dimensions | 445 x 295 x 165 mm |

| Weight | 11 kg |

| Mounting to vehicle | All other orientation allowed than cables upside and service switch upside. |

| Mounting | Customer designed brackets |

Main dimensions illustrate prototype development status and may subject to change.

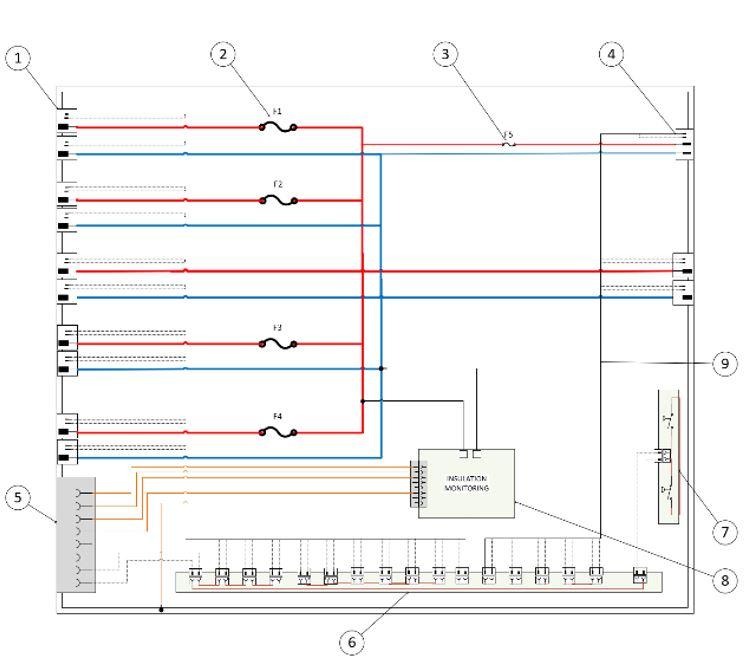

Simple High voltage circuit control block diagram for passive PDU

- Powerlock HC IPxxB complient connector

- Main fuses high current (HC)

- Low current auxiliary fuses (LC)

- ePowerlite IPXXB compliant connectors

- Signal connector

- HVIL PWB

- Sensor PWB

- Insulation monitoring unit (optional)

FINNISH KNOWLEDGE

tested, designed and produced in finland.

Epec control systems are made 100% in Finland. We are a control system expert, specializing in intelligent control systems and information systems for even the most demanding conditions. Epec’s organization and processes have been fine tuned to cooperate with large international customers.

Harsh conditions?

Bring it on!

All Epec control units are designed and manufactured to withstand harsh conditions:

high mechanical shocks and vibration, heat, cold and different chemicals.